What is CNC Machining and CNC Machines?

-Best Practices to Boost Productivity

CNC (Computer Numerical Control) is a fundamental technology that drives modern manufacturing. CNC machines automatically perform high-precision operations based on NC programs generated from CAD and CAM systems. They are widely used across industries such as automotive, mold making, aerospace, and medical devices. However, the accuracy of NC programs is critical. Even a small error can cause tool breakage, material waste, and significant cost losses.

_edited.jpg)

Types of CNC Machines

-

Milling Machines – Essential for mold making and part production.

-

Lathes – Ideal for fast, precise turning of cylindrical workpieces.

-

Wire EDM Machines – Indispensable for high-precision mold and die manufacturing.

-

Laser / Plasma Cutters – Common in sheet metal processing and prototyping.

Challenges in CNC Operations

-

Program errors that cause tool or machine damage.

-

High costs and downtime from real machine test runs.

-

Difficulty for operators to fully understand NC programs at a glance.

These challenges reduce the efficiency and safety of CNC machines.

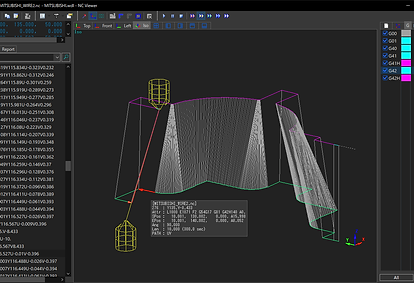

The Solution: NC Viewer

System-I’s NC Viewer is a CNC simulator that offers the smart solution to support CNC operations.

-

Detect errors with G-code analysis

-

Visualize tool paths with 3D simulation

-

Estimate machining time in advance

-

Lightweight and easy-to-use interface

With NC Viewer, you can verify NC programs before running the CNC machine, reducing errors, saving time, and increasing productivity.

To maximize the potential of CNC machines, safe and efficient NC program validation is essential.

NC Viewer is the tool that makes it possible.